News

What procedures do gift box customization go through

The first step is needs analysis. In this stage, you determine the purpose of the gift box, target audience, product size, packaging style, and budget. This information helps define the basic direction of the design and ensures the box meets functional and branding requirements.

The second step is structural design. Based on product dimensions and protection needs, packaging designers create a suitable box structure such as a lid-and-base box, drawer box, magnetic box, folding box, or corrugated mailer. A well-designed structure ensures both durability and a premium unboxing experience.

The third step is visual design. Designers develop the artwork including colors, logos, patterns, text, finishing effects, and overall style. A strong visual design communicates brand value, improves recognition, and creates a stronger connection with customers.

The fourth step is material selection. Different industries require different packaging materials. Common options include coated paper, kraft paper, specialty paper, greyboard, corrugated board, and eco-friendly materials. The material affects the box’s appearance, durability, and cost, so choosing the right one is essential.

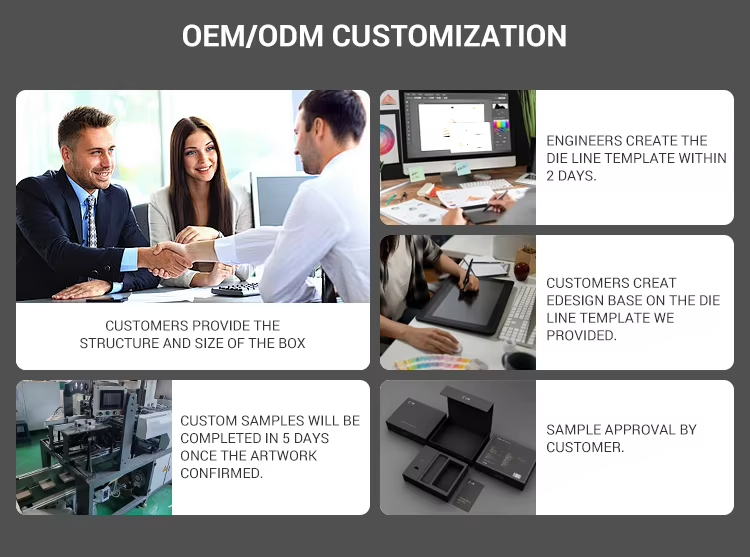

The fifth step is sample production. Before mass production, manufacturers create a physical sample or prototype. This allows you to check structure, printing quality, color accuracy, and finishing details. Any necessary adjustments can be made at this stage to avoid mistakes during final production.

The sixth step is mass production. Once the sample is approved, manufacturers begin large-scale printing, cutting, laminating, gluing, and assembling. Quality control is performed throughout the process to maintain consistent standards and ensure every box meets the design expectations.

The seventh step is surface finishing. Popular finishing options include matte or glossy lamination, embossing, debossing, foil stamping, spot UV, and textured coatings. These enhancements improve visual appeal, brand value, and customer experience.

The final step is packaging and delivery. Finished gift boxes are inspected, packed, and shipped according to your requirements. Proper packaging ensures the boxes arrive safely without deformation or damage.

Understanding the complete workflow of gift box customization helps businesses communicate better with suppliers and achieve high-quality packaging that reflects their brand. A well-customized gift box increases product value, enhances customer satisfaction, and improves overall market competitiveness.

RELATED NEWS

- What Are the Precautions for Designing a Handbag? | Custom Packaging Solutions

- Christmas packaging – paper box solution

- Custom Boxes That Brand Your Business

- How the European EPR Packaging Law Is Upgrading Our Paper Box and Gift Packaging

- Why Pay Attention to Color Matching When Customizing Cardboard Boxes

CATEGORIES

LATEST NEWS

CONTACT US

Name: Zara Liu

Mobile:+86 19928778203

Tel:+86 19928778203

Whatsapp:8619928778203

Email:print@xinjiatengbox.com

Add:Yizheng Group, No. 6 Xiangshan Avenue, Yanluo Community, Bao'an, Shenzhen